|

|

|

|

Honda CBR 1000RR Baseline Dyno Runs

May 2005

This article will discuss the base line dyno runs I had done to get an idea of what kind of power my 1000RR was putting to the ground. I wanted to do base line runs so I would know what I gained from my new exhaust as well as the PC3USB I ordered. I also wanted to test a few things such as the flapper mod, disabling the PAIR system, and modifying the stock exhaust to put to rest some of the questions regarding what the various modifications do for the motor's power delivery. I then took the actual dyno run files home with me on a floppy disk and used Dynojet's RunViewer 7.0 software to analyze the data. All graphs and numbers quoted in this article use a standard correction factor and smoothing of 4.

I happen to be fortunate enough to work within 10 minutes of a Dynojet Approved Power Commander Tuning center that has a Dynojet 250i dynamometer, TNT Performance Dyno in Nashville, TN. Konrad and his lovely wife Melinda are the owners and are wonderful people to work with. Konrad is a wizard with mechanics, custom builds bikes, and has custom fabricated his dyno into a box truck so that it is mobile. If you have an event or other function give them a shout as he can do on the spot tuning, custom mapping, and dyno readings. I've had Konrad work on three different motorcycles and he has always done good work and both he and Melinda go out of their way to make you feel at home in their shop.

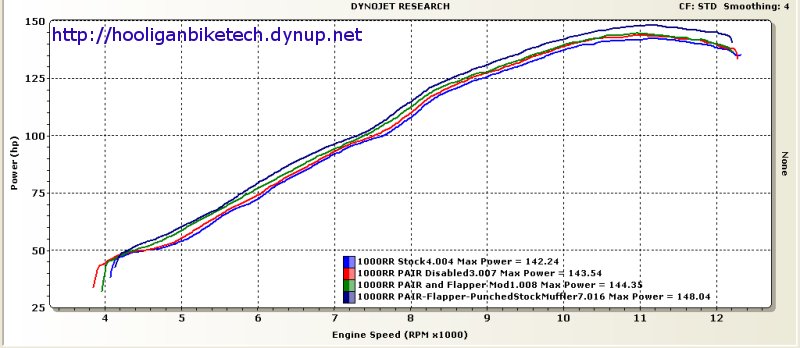

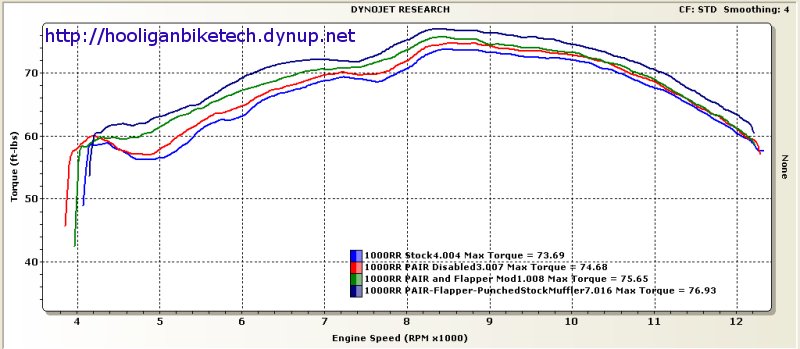

Konrad strapped the 1000RR to the dyno and began taking preliminary A/F ratio readings, and checking out the over all settings of the bike. Once things had been brought up to operating temperature he did three runs totally stock. The bike pulled a max HP of 142.24HP and 73.69 ft lbs of torque.

|

|

|

|

We then disabled the PAIR system to see what effect that would have on the A/F ratios. The difference was quite prevalent especially during anything under 7,000 RPMs. The PAIR system caused the dyno to read leaner than when the PAIR system was disabled. The odd thing to me was that the bike gained 1.3HP and 1 ft lb of torque as well. Konrad and I discussed this and theorized that disabling the PAIR system must allow more volume of exhaust to fill the exhaust chamber, thus the increase. I still don't know if it's worth disabling this system for little more than 1HP considering the difference it makes in emissions. The numbers from this dyno run were 143.54HP and 74.68 ft lbs of torque.

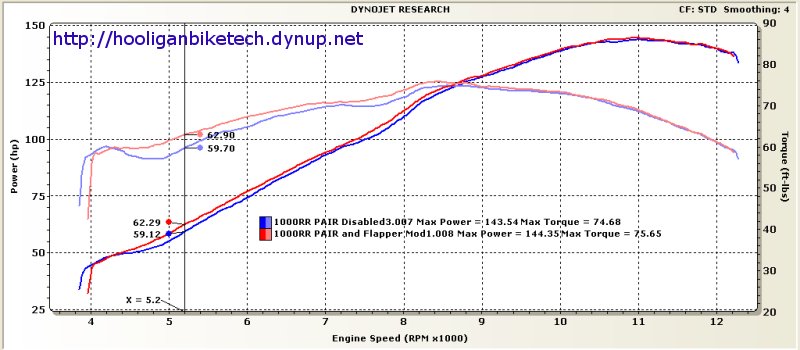

We then plugged the flapper vacuum line to see what affect this had on power delivery. I expected some HP gain down low in the RPM range, but I was very pleasantly surprised to see a 3.2HP gain and 3.2 ft lbs of torque gain in the lower RPM range. Considering how easy this modification is to make, I highly recommend it as it has no negative effects on the bike or the environment. Below is the dyno graph showing the difference between the PAIR system disabled run vs. the PAIR and flapper mod run at 5200RPMs. The fact that the graph shows a significant gain down low proves the flapper mod is worth while. With the PAIR and flapper mods completed the total gain over stock at 5200RPMs is now 5.2HP and 5.3 ft lbs of torque. Not bad for free HP considering most HP costs around $100 US per single HP gained.

At this point I was thinking we were through testing. I began talking to Konrad about getting a slip on exhaust and PC3USB. He said since I was a testing kinda guy, why not punch out the stock exhaust baffles just to see what could be gained. I agreed and he began working on the stock muffler making large holes in the baffles. Once the work was complete we ran the dyno test. I was surprised to see a gain of 3.7HP and 1.3 ft lbs of torque over the PAIR and flapper mod run. The total over all gain compared to stock was 5.8HP and 3.2 ft lbs of torque and there is power gained throughout the entire RPM range! The more important thing is that significant power was gained in the more usable RPM ranges. At 6000 RPMs the gain over stock is 6.8HP and 6 ft lbs of torque. At 8000 RPMs the gain was 6.9HP and 4.5 ft lbs of torque. The max numbers were 148.04HP and 76.93 ft lbs of torque vs. stock at 142.24HP and 73.69 ft lbs of torque.

Not bad at all for free HP. The sound of the gutted stock exhaust is quite unique. It sounds pretty good and similar to that of D&D if you've ever heard one of those. A tad loud, but not screaming, and very throaty. I've learned from these tests to recommend the flapper mod and gutting the stock exhaust to anyone who owns a 1000RR and wants to eeek a little more HP out of the motor. I'll post an update when I get my aftermarket exhaust installed. I plan to do base runs with it to see what is gained over the mods mentioned here. I'll then have a custom map created and again test to see how much more is gained. That information will be in future articles.

The max dyno run graphs are below followed by the torque graphs. I put them in separate images to make them easier to read.

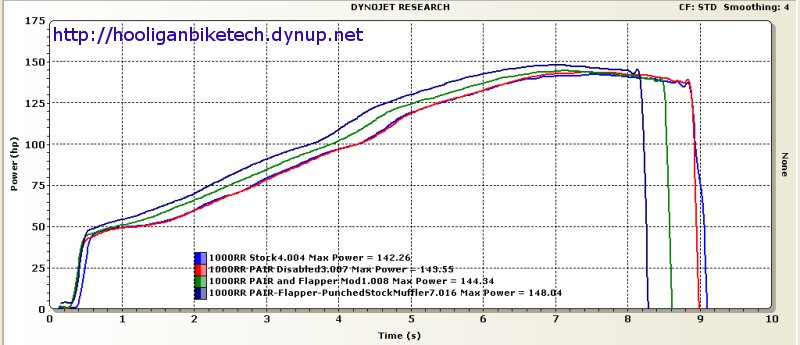

Below is a graph showing the different max dyno runs as a function of time. Opening up the flapper decreased the time required to reach redline by nearly a full second! Opening the stock exhaust decreased the time again by about .5 seconds.

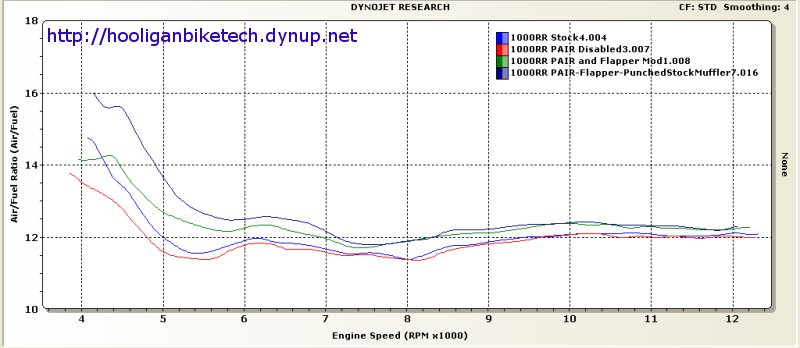

Air Fuel ratios are very important to the performance of an engine. As you can see in the graphs below, opening the exhaust made a huge difference in the A/F ratio. The higher the number the leaner the reading. A PC3USB and map should add even more power, I'd guess around 3 to 4HP in various places in the RPM range as the PC3USB will allow the proper fuel to be delivered at the proper time. I'm told 13 is a good number to stay around which corresponds to 13 parts air to 1 part fuel. Notice how lean the graph is below 5,000 RPMs. Most EPA tests are done around 5,000 RPMs. Coincidence?

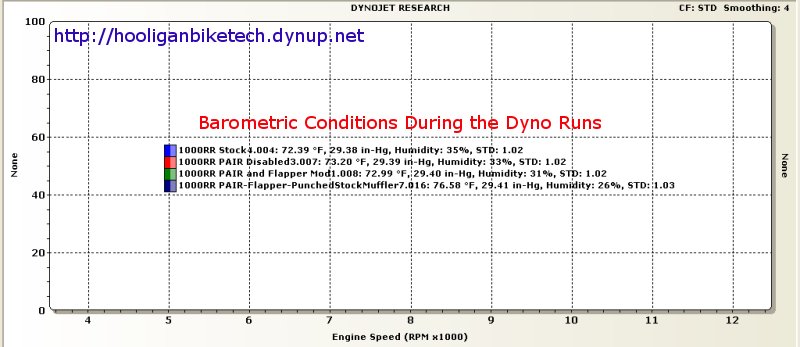

For those interested, the barometric conditions during my runs are below:

This page is part of a frame set. If you reached this page via a search engine please click here to go to the main page.